Experimental investigation and artificial intelligence modeling of stability of Agbabu Bitumen Emulsion using green-based surfactant

DOI:

https://doi.org/10.57056/ajet.v9i1.163Keywords:

Emulsion, Agbabu bitumen, Stability, Characterization, Artificial intelligenceAbstract

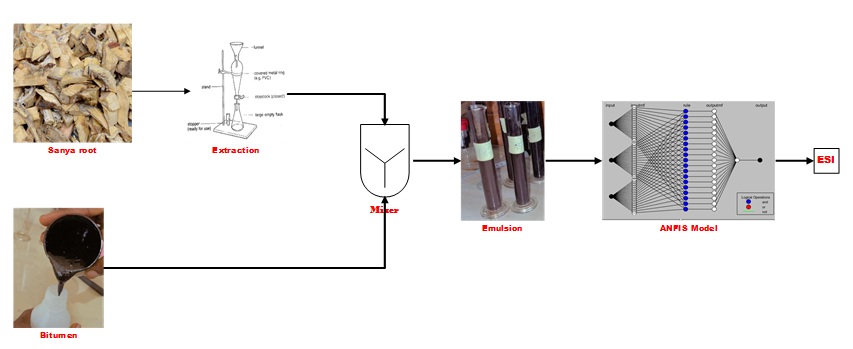

One of the challenges that affected the optimal utilization of 42.47 billion tons of natural bitumen deposit in Nigeria is its high viscosity and high pumping cost in current state. This research investigated the possibility of reducing viscosity of Agbabu Bitumen (AB) through formation of emulsion using plant sourced surfactant solution. AB Emulsion (ABE) was prepared by homogenizing 60 vol. % of bitumen and 40 vol. % of water in the presence of surfactant solution extracted from Sanya root bark (surfactant solution was varied with respect to the volume of aqueous phase). Effect of increase in volume of extract, pH and salinity of extract was tested on the stability of the prepared emulsion. Emulsification Stability Index (ESI) was computed for all ABE prepared. Viscosity, pour, flash and fire point were determined for the emulsion formed while further analysis were conducted on the emulsion using Scanning Electron Microscope (SEM), Energy Dispersive X-ray (EDX) and Fourier Transform Infrared (FTIR) spectroscopy. The surfactant solution extracted ABE prepared from AB and water which was enhanced in alkaline solution, a 64% reduction in viscosity was recorded in emulsion prepared, and the pour point of emulsion drastically reduced when compared with that of AB.

References

Olabemiwo OM, Esan AO, Bakare O. Preliminary Investigation on Modification of Agbabu Natural Bitumen with Some Polymeric Materials. Int. J. Sci. Eng. Res. 2015;6(9):1342–1349.

Hasan SW, Ghannam MT, Esmail N. Heavy crude oil viscosity reduction and rheology for pipeline transportation. Fuel. 2010;89(5):1095–1100. https://doi.org/10.1016/j.fuel.2009.12.021.

3. Hart A. REVIEW PAPER - PRODUCTION ENGINEERING A review of technologies for transporting heavy crude oil and bitumen via pipelines. J. Pet. Prod. Technol. 2014;4:327–336. https://doi.org/10.1007/s13202-013-0086-6.

4. Yuliestyan A, García-Morales M, Moreno E, Carrera V, Partal P. Assessment of modified lignin cationic emulsifier for bitumen emulsions used in road paving. Mater. Des. 2017;131:242–251. https://doi.org/10.1016/j.matdes.2017.06.024.

Mohsin S, Akhtar N, Mahmood T, Khan H, Mustafa R. Formulation and stability of topical water in oil emulsion containing corn silk extract. Trop. J. Pharm. Res. 2016;15(6):1115–1121. https://doi.org/10.4314/tjpr.v15i6.1.

Chaverot P, Cagna A, Glita S, Rondelez F. Interfacial Tension of Bitumen - Water Interfaces. Part 1: Influence of Endogenous Surfactants at Acidic pH. 2008;9:790–798.

Gingras J, Fradette L, Tanguy P, Bousquet J. Inline Bitumen Emulsification Using Static Mixers. Ind. Eng. Chem. Res. 2007;46:2618–2627.

8. Alade OS, Sasaki K, Sugai Y, Ademodi B, Kumasaka J, Nakano M. Prospects of Bitumen Emulsification using a Hydrophilic Polymeric Surfactant. 2015;4(1):55–59. https://doi.org/10.12783/ijepr.2015.0401.12.

dos Santos RG, Bannwart AC, Briceño MI, Loh W. Physico-chemical properties of heavy crude oil-in-water emulsions stabilized by mixtures of ionic and non-ionic ethoxylated nonylphenol surfactants and medium chain alcohols. Chem. Eng. Res. Des. 2011;89(7):957–967. https://doi.org/10.1016/j.cherd.2010.11.020.

Kumar S, Mahto V. Emulsification of Indian heavy crude oil in water for its efficient transportation through offshore pipelines. Chem. Eng. Res. Des. 2016. https://doi.org/10.1016/j.cherd.2016.09.017.

Krstono V, Dokic L, Nikolic I, Milanovic M. Influence of xanthan gum on oil-in-water emulsion characteristics stabilized by OSA starch. Food Hydrocoll. 2015;45:9–17. https://doi.org/10.1016/j.foodhyd.2014.10.024.

Sethuraman S, Rajendran K. Is Gum Arabic a Good Emulsifier Due to CH... π Interactions? How Urea Effectively Destabilizes the Hydrophobic CH... π Interactions in the Proteins of Gum Arabic than Amides and GuHCl? 2019. https://doi.org/10.1021/acsomega.9b01980.

Kirtil E, Oztop MH. Characterization of emulsion stabilization properties of quince seed extract as a new source of hydrocolloid. Food Res. Int. 2016;85:84–94. https://doi.org/10.1016/j.foodres.2016.04.019.

Kumar R, Banerjee S, Naiya TK. Flow improvement of heavy crude oil through pipelines using surfactant extracted from soapnuts. J. Pet. Sci. Eng. 2017. https://doi.org/10.1016/j.petrol.2017.02.010.

Maurad ZA, Abdullah LC, Anuar MS, Shah NN, Idris Z. Preparation, characterization, morphological and particle properties of crystallized palm-based methyl ester sulphonates (MES) powder. Molecules. 2020;25(11). https://doi.org/10.3390/molecules25112629.

Xu W, Bian P, Gang H, Liu J, Mu B, Yang S. A novel bio-based sulfonic zwitterionic surfactant derived from transgenic soybean oil and its performance in surface and interfacial activities. J. Pet. Sci. Technol. 2018;8(1):32–44.

17. Liu Z, Biresaw G. Synthesis of soybean oil-based polymeric surfactants in supercritical carbon dioxide and investigation of their surface properties. J. Agric. Food Chem. 2011;59(5):1909–1917. https://doi.org/10.1021/jf1035614.

Jin Y, Tian S, Guo J, Ren X, Li X, Gao S. Synthesis, Characterization and Exploratory Application of Anionic Surfactant Fatty Acid Methyl Ester Sulfonate from Waste Cooking Oil. J. Surfactants Deterg. 2016;19(3):467–475. https://doi.org/10.1007/s11743-016-1813-z.

Szelag H, Sadecka E, Pawlowicz R, Kuziemska A. Emulsifiers from renewable materials: An eco-friendly synthesis and properties. Polish J. Chem. Technol. 2013;15(2):128–135. https://doi.org/10.2478/pjct-2013-0035.

Slamet S, Fachry Y, Levi R. Utilization of Jatropha Oil as Feedstock for Synthesis of Methyl Ester Sulfonate Surfactant. 2018;020033. https://doi.org/10.1063/1.5064319.

Elraies KA, Tan IM, Awang M, Saaid I. The synthesis and performance of sodium methyl ester sulfonate for enhanced oil recovery. Pet. Sci. Technol. 2010;28(17):1799–1806. https://doi.org/10.1080/10916460903226072.

Bachari Z, Isari AA, Mahmoudi H, Moradi S, Mahvelati EH. Application of Natural Surfactants for Enhanced Oil Recovery-Critical Review. IOP Conf. Ser. Earth Environ. Sci. 2019;221(1). https://doi.org/10.1088/1755-1315/221/1/012039.

Onyema AM, Finchiwa J, Anthony HJ. Analytical investigation of foam formation and emulsifying power of Sanya (Securidaca Longepedunculata) roots and comparison with some commercial / synthetic surfactants. Int. J. Eng. Sci. 2013;2(9):8–15.

Makinia WE, Ojunga M, Ayayo ZN. Efficacy of Securidaca longipedunculata Fresen (Polygalaceae) against Two Standard Isolates of Neisseria gonorrhoeae. Int. J. Biochem. Res. Rev. 2020;61–68. https://doi.org/10.9734/ijbcrr/2020/v29i630199.

Tikisa T, Abdissa D, Abdissa N. Chemical constituents of Securidaca longipedunculata root bark and evaluation of their antibacterial activities. Ethiop. J. Educ. Sci. 2019;14(2).

26. Abubakar US, Danmalam UH, Ibrahim H, Maiha BB. A Review on African Violet Tree (Securidaca longipedunculata): A Traditional Drug with Multiple Medicinal Uses. Spec. J. Chem. 2019;4(3):7–14. Available from: https://sciarena.com/storage/models/article/xUYsLsgS38HwvwmJbgbnvJqE0jrKLv7olantef7uJy0jWMhMnQUhXYPXX3E1/a-review-on-african-violet-tree-securidaca-longipedunculata-fresen-a-traditional-drug-with-multipl.pdf.

Lijalem T, Feyissa T. In vitro propagation of Securidaca longipedunculata (Fresen) from shoot tip: an endangered medicinal plant. J. Genet. Eng. Biotechnol. 2020;18(1). https://doi.org/10.1186/s43141-019-0017-0.

Olowonyo IA, Salam KK, Omolara AM, Lateef A. Synthesis, characterization, and adsorptive performance of titanium dioxide nanoparticles modified groundnut shell activated carbon on ibuprofen removal from pharmaceutical wastewater. Waste Manag. Bull. 2024;1(4):217–233. https://doi.org/10.1016/j.wmb.2023.11.003.

Salam KK, Emmanuel S, Oke C, Joan O, Umar U. Multi-objectives regression, optimization and risk assessment of profitability indicators of the simulation of mini Liquefied Petroleum Gas (LPG) dispensing unit. Alger. J. Eng. Technol. 2023;8:288–301.

Oke EO, et al. Heterogeneously catalyzed biodiesel production from Azadiricha Indica oil: Predictive modelling with uncertainty quantification, experimental optimization and techno-economic analysis. Bioresour. Technol. 2021;332:1–11. https://doi.org/10.1016/j.biortech.2021.125141.

Salam K, Emmanuel S, Oke C, OlusolaJoan, Umar U. Zeolite-Y-based catalyst synthesis from Nigerian Elefun Metakaolin: computer-aided batch simulation, comparative predictive response surface and neuro-fuzzy modelling with optimization. Chem. Pap. 2022;76(2):1213–1224. https://doi.org/10.1007/s11696-021-01931-1.

Irshaid M, Abu-eisheh S. Application of adaptive neuro-fuzzy inference system in modelling home-based trip generation. Ain Shams Eng. J. 2023;14(11):102523. https://doi.org/10.1016/j.asej.2023.102523.

Kassem Y, Çamur H, Esenel E. Adaptive neuro-fuzzy inference system (ANFIS) and response surface methodology (RSM) prediction of biodiesel dynamic viscosity at 313 K. Procedia Comput. Sci. 2017;120:521–528. https://doi.org/10.1016/j.procs.2017.11.274.

Chopra S, Dhiman G, Sharma A, Shabaz M, Shukla P, Arora M. Taxonomy of Adaptive Neuro-Fuzzy Inference System in Modern Engineering Sciences. Comput. Intell. Neurosci. 2021;2021. https://doi.org/10.1155/2021/6455592.

Babatunde KA, Salam KK, Aworanti OA, Arotiowa OA, Alagbe SO, Oluwole TD. Transesterification of castor oil: neuro-fuzzy modelling, uncertainty quantification and optimization study. Syst. Microbiol. Biomanufacturing. 2022;1–12. https://doi.org/10.1007/s43393-022-00120-9.

Geena K, Suguna M, Ragunath PN. Study on Adaptive Neuro-Fuzzy Inference System (ANFIS). Int. J. Futur. Gener. Commun. Netw. 2020;13(3):4205–4217.

Obianyo JI, Udeala RC, Alaneme GU, Mean-absolute-error MAE. Application of neural networks and neuro-fuzzy models in construction scheduling. Sci. Rep. 2023;1–23. https://doi.org/10.1038/s41598-023-35445-5.

Singh I, Kaur J, Kaur S, Barik B, Pahwa R. Artificial Neural Networks and Neuro-Fuzzy Models: Applications in Pharmaceutical Product Development. Brazilian Arch. Biol. Technol. 2023;66.

Benderrag A, Daaou M, Bounaceur B, Haddou B. Influence of pH and cationic surfactant on stability and interfacial properties of Algerian bitumen emulsion. Chem. Pap. 2016;70(9):1196–1203. https://doi.org/10.1515/chempap-2016-0061.

Daaou M, Bendedouch D. Water pH and surfactant addition effects on the stability of an Algerian crude oil emulsion. J. Saudi Chem. Soc. 2012;16(3):333–337. https://doi.org/10.1016/j.jscs.2011.05.015.

Ashrafizadeh SN, Motaee E, Hoshyargar V. Emulsification of heavy crude oil in water by natural surfactants. J. Pet. Sci. Eng. 2012;86-87:137–143. https://doi.org/10.1016/j.petrol.2012.03.026.

Abdullin AI, Emelyanycheva EA. Water-bitumen emulsions based on surfactants of various types. J. Chem. Technol. Metall. 2020;55(1):73–80.

Choi P-S, Seung Jun W, Jong Won P, Kyung Min C. A new method for determining the emulsion stability index by backscattering light detection. J. Food Process. Eng. 2014;37:229–236.

ASTM F1372-93. Standard Test Method for Scanning Electron Microscope (SEM) Analysis of Metallic Surface Condition for Gas Distribution System Components. 2020.

ASTM F1375-92. Standard Test Method for Energy Dispersive X-Ray Spectrometer (EDX): Analysis of Metallic Surface Condition for Gas Distribution System Components. 2020.

ASTM D8254-19. Standard Test Method for Flash and Fire Points of Asphalt by Cleveland Open Cup Tester. 2019.

ASTM D97-17b. Standard Test Method for Pour Point of Petroleum Products. 2017.

ASTM D445-21. Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). 2021.

ASTM E1252-98. Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis. 2021.

Aremu MO, Oke EO, Arinkoola AO, Salam KK. Development of Optimum Operating Parameters for Bioelectricity Generation from Sugar Wastewater Using Response Surface Methodology. J. Sci. Res. Reports. 2014;3(15):2098–2109.

51. Salam KK, Araromi DO, Arinkoola AO, Ikiensikimama SS, Harcourt P. Fuzzy Sequential Forward Search for Oil Formation Volume Factor Predictive Tool Factor for Niger Delta Crude Oil. 2013;3(1):91–106.

52. Salam KK, Araromi D, Ikiensikimama SS. Neuro-fuzzy modeling for the prediction of below-bubble-point viscosity. Pet. Sci. Technol. 2011;29(17). https://doi.org/10.1080/10916460903581401.

Nkafamiya I, Honda J, Eneche J, Haruna M. Extraction and Evaluation of a Saponin-base Surfactant from Cissus populnea Plant as an Emulsifying Agent. Asian J. Chem. Sci. 2018;4(1):1–7. https://doi.org/10.9734/ajocs/2018/39509.

Ogiriki SO, Adepoju JO, Yusuff AS, Anochie V. Physical Properties of Agbabu and Yegbata Bitumen in Nigeria. J. Appl. Sci. Process Eng. 2018;5(1):227–241. https://doi.org/10.33736/jaspe.427.2018.

Kumar S, Mahto V. Emulsification of Indian heavy crude oil using a novel surfactant for pipeline transportation. Pet. Sci. 2017;14(2):372–382. https://doi.org/10.1007/s12182-017-0153-6.

Sharma R, Deka B, Mandal A, Mahto V. Study the influence of sodium dodecyl sulfate on emulsification of heavy and waxy crude oils to improve their flow ability in low temperature conditions. Asia-Pacific J. Chem. Eng. 2019;14(1):1–16. https://doi.org/10.1002/apj.2279.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Ojeyemi Mattew Olabemiwo, Kazeem Kolapo Salam, Dauda Olurotimi Araromi, Mujidat Omolara Aremu, Akeem Olatunde Arinkoola, Abdulfatai Ayodeji Faro

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.