Multi-objectives regression, optimization and risk assessment of profitability indicators of the simulation of mini Liquefied Petroleum Gas (LPG) dispensing unit

DOI:

https://doi.org/10.57056/ajet.v8i2.136Keywords:

Profitability indices, Energy, Uncertainty analysis, Response surface methodology, Techno-Economic AnalysisAbstract

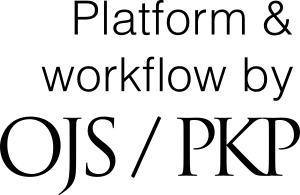

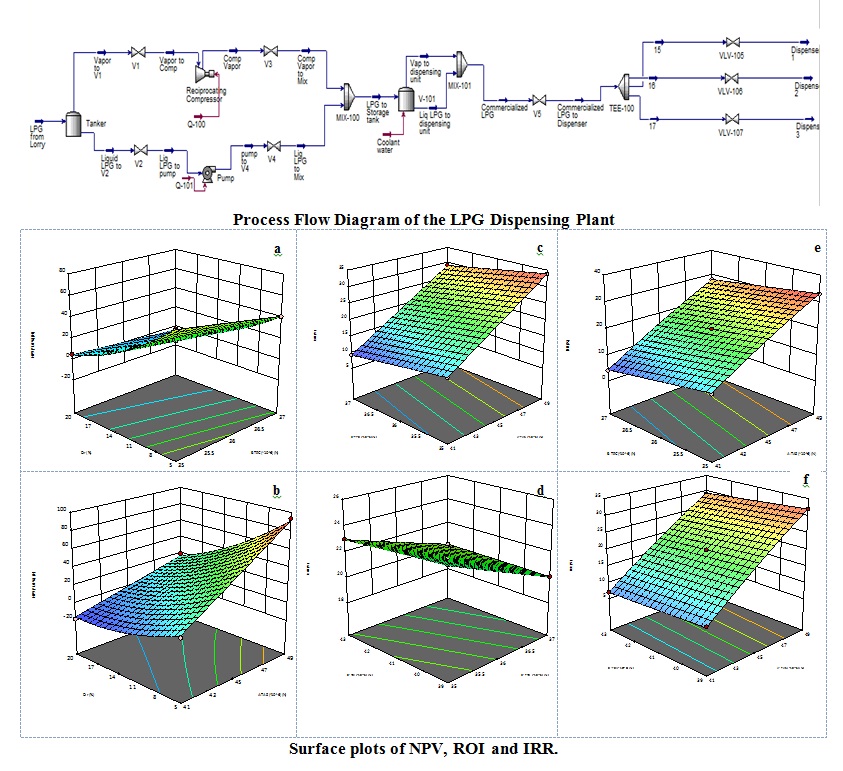

In this study, simulation of a mini Liquefied Petroleum Gas (LPG) dispensing unit was conducted using ASPEN HYSYS and the operation of both compressor and pump were validated theoretically. The effect of the economic parameters (Total Annual Sales (TAS), Total Production Cost (TPC), Fixed Capital Investment (FCI) and interest rate (r)) on the behaviour of three profitability indicators (Net Present Value (NPV), Return on investment (ROI) and Internal Rate of Return (IRR)) were modelled and optimized using Box Behnken Design (BBD). The uncertainty of the developed models was determined using Oracle Crystal Ball (ORB). The optimum economic parameters, TAS of ₦48,830,600, FCI of ₦37,422,000, TPC of ₦35, 053,000 and r of 5.4% predicted optimum profitability indicators are ROI of 34.6%, NPV of ₦98,993,580.25 and IRR of 34.15% for 15 years’ investment plan. An interaction of the economic parameters showed that for NPV to be positive, TAS value should be greater than ₦42.5 million and the TPC should be less or equal to ₦36 million. The profitability analysis suggested that this investment will pay back in 2.36 years. Given that the demand of LPG is on the increase and therefore, this LPG plant will be a long term investment with a good return on investment.

References

Ali U, Zafar M, Ahmed A, Zaman HK, Razzaq A, Daood SS, Bashir M, Park YK. Techno commercial analysis of liquefied petroleum gas recovery from natural gas using Aspen HYSYS. Frontiers in Energy Research. 2021;9:785827. https://doi.org/10.3389/fenrg.2021.785827.

ElBadawy KM, Teamah MA, Shehata AI, Hanfy AA. Simulation of Liquefied Petroleum Gas (LPG) Production from Natural Gas Using Fractionation Towers. International Journal of Advanced Scientific and Technical Research. 2017;6(7):148-153. 2018, https://doi.org/10.26808/rs.st.i7v6.16.

Brown ED, Stephen K. Natural resource abundance and economic growth in Nigeria (1980–2015). Global Journal of Agricultural Research. 2017;5(3):2053–5813.

Tyger TF, Yelebe ZR. Simulation of a Natural Gas Liquid ( NGL ) Extraction Plant for Processing Associated Gas Flare Stream. Int. J. Eng. Technol. Creat. Innov. 2(1):1–19, 2019.

Godwin UM, Ogbonna JF, Boma KS. Simulation and Improved Recovery of Liquified Petroleum Gas from Flare System (Case Study: Niger Delta, Nigeria). Int. J. Sci. Eng. Res., 2018; 9(4):1665–1673.

Raheem AB, Hassan A, Samsudin SA, Noor ZZ, Adebobajo A. Comparative economic investigation options for liquefied petroleum gas production from natural gas liquids. American Journal of Chemical Engineering. Special Issue: Developments in Petroleum Refining and Petrochemical Sector of the Oil and Gas Industry. 2015;3(2-1):55-69. https://doi.org/10.11648/j.ajche.s.2015030201.17.

Carim AA, Onyekonwu MI. Review of gas resource utilization using applicable technologies: a case study of Nigeria. Int. J. Eng. Sci. 2016;5(3):71-78.

Kolawole A, Ikubanni PP, Adeleke AA, Alaka OS, Agboola OO. MODELING OF A PLANT LAYOUT FOR A LIQUIFIED PETROLEUM GAS REFILLING PLANT. Journal of Chemical Technology & Metallurgy. 2020;55(6)2049–2060.

Ozoh OB, Okwor TJ, Adetona O, Akinkugbe AO, Amadi CE, Esezobor C, Adeyeye OO, Ojo O, Nwude VN, Mortimer K. Cooking fuels in Lagos, Nigeria: factors associated with household choice of kerosene or liquefied petroleum gas (LPG). International journal of environmental research and public health. 2018;15(4):641. https://doi.org/10.3390/ijerph15040641.

Hammeed GA, Orifah OM, Ijeoma MC, Tijani SA. Assessment of the use of liquefied petroleum gas (LPG) as cooking energy source among rural households in Badagry Area of Lagos State. American Scientific Research Journal for Engineering, Technology, and Sciences (ASRJETS). 2016;18(1):16-28. [Online]. Available: http://asrjetsjournal.org/.

Ihemtuge TU, Aimikhe VJ. Optimization of liquefied petroleum gas (LPG) distribution in Nigeria. Int J Eng Tech Res. 2020;10(5)1–7. https://doi.org/10.31873/ijetr.10.5.83.

Maria A. Introduction to modeling and simulation. InProceedings of the 29th conference on Winter simulation 1997 Dec 1 (pp. 7-13). https://doi.org/10.1145/268437.268440.

Mondal SK, Uddin MR, Azad AK. Simulation and optimization of natural gas processing plant. InInternational conference on mechanical, industrial and materials engineering, Bangladesh 2013 Jan 1 (pp. 485-490). https://doi.org/10.13140/2.1.4347.0720.

Salam KK, Arinkoola AO, Ajagbe BM. BI-OPTIMIZATION OF DURABILITY AND RHEOLOGICAL PERFORMANCE OF OIL WELL CEMENT SLURRY USING LOCALLY SOURCED EXTENDER. The Journal of Engineering Research. 2022;19(1):73-84. https://doi.org/10.53540/tjer.vol19iss1pp73-84.

Mahfud M, Ansori A. Box-Behnken design for optimization on biodiesel production from palm oil and methyl acetate using ultrasound assisted interesterification method. Periodica Polytechnica Chemical Engineering. 2022;66(1):30-42. https://doi.org/10.3311/PPch.17610.

Rodr?guez-Ram?rez R, Romero-Ibarra I, Vazquez-Arenas J. Synthesis of sodium zincsilicate (Na2ZnSiO4) and heterogeneous catalysis towards biodiesel production via Box-Behnken design. Fuel. 2020;280:118668. https://doi.org/10.1016/j.fuel.2020.118668.

Aalde H, Gonzalez P, Gytarsky M, Krug T, Kurz WA, Ogle S, Raison J, Schoene D, Ravindranath NH, Elhassan NG. IPCC guidelines for national greenhouse gas inventories. Forest Land. 2006; 157–169.

Volodina V, Challenor P. The importance of uncertainty quantification in model reproducibility. Philosophical Transactions of the Royal Society A. 2021;379(2197):20200071. https://doi.org/10.1098/rsta.2020.0071.

Babatunde EO, Saka HB, Olutoye MA, Akpan UG, Auta M. Synthesis of fatty acid methyl esters from used vegetable oil using activated anthill as catalyst. Nigerian Journal of Technology. 2020;39(1):140-147. https://doi.org/10.4314/njt.v39i1.15.

Sinnot R, Chemical Engineering Design Coulson and Richardson Chemical Engineering Series, 4th ed. Elsevier Butterworth-Heinemann, 2005.

Peterson MS and Timmerhaus KD, Plant Design and Economics for Chemical Engineers, 4th ed. McGraw-Hill, 1991.

Towler G, Sinnot R, Chemical Engineering Design; Principles, Practice and Economics of Plant and Process Design, 2nd ed. Elsevier, 2013.

Saliem MS, Bhran AA, Abdel-Aleim GM, Hady AA. Process Simulation and Performance Improving of An Existing Ngl Plant. Journal of Petroleum and Mining Engineering. 2015 Dec 1;17(1):86-94. https://doi.org/10.21608/jpme.2015.43872.

Turton R, Whiting W, Shaeiwitz J, Analysis synthesis and design of chemical processes, 2nd ed. New Jersey: Princehall, 2009.

Gebremariam SN, Marchetti JM. Economics of biodiesel production. Energy Conversion and Management. 2018;168:74-84. https://doi.org/10.1016/j.enconman.2018.05.002.

Sinnott RK, Coulson JM, Richardson JF, Coulson & Richardson’s chemical engineering: Vol. 6. Oxford: Elsevier Butterworth-Heinemann, 2005.

Ochoa S, Durango-Zuleta MM, Osorio-Tob?n JF. Techno-economic evaluation of the extraction of anthocyanins from purple yam (Dioscorea alata) using ultrasound-assisted extraction and conventional extraction processes. Food and Bioproducts Processing. 2020;122:111-123. https://doi.org/10.1016/j.fbp.2020.04.007.

Oke EO, Adeyi O, Okolo BI, Ude CJ, Adeyi JA, Salam KK, Nwokie U, Nzeribe I. Heterogeneously catalyzed biodiesel production from Azadiricha Indica oil: Predictive modelling with uncertainty quantification, experimental optimization and techno-economic analysis. Bioresource Technology. 2021;332:125141., https://doi.org/10.1016/j.biortech.2021.125141.

Babatunde KA, Salam KK, Aworanti OA, Olu-Arotiowa OA, Alagbe SO, Oluwole TD. Transesterification of castor oil: neuro-fuzzy modelling, uncertainty quantification and optimization study. Systems Microbiology and Biomanufacturing. 2022:1-2. https://doi.org/10.1007/s43393-022-00120-9.

Agbadede R, Kainga B. Techno-economic analysis of the influence of different operating conditions on gas turbine centrifugal compressor set performance. Nigerian Journal of Technology. 2020;39(4):1150-1157. https://doi.org/10.4314/njt.v39i4.23.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Kazeem Kolapo Salam, Kehinde Ayoola Babatunde, Akeem Olatunde Arinkoola, Titilayo Deborah Oluwole, Dolapo Aremu, Usman Olalekan Oladapo, Suliyat Omolara Ibrahim

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.