Strength of glass powder based high performance concrete during the time

DOI:

https://doi.org/10.57056/ajet.v8i1.99Keywords:

Algerian cement, Glass powder, High Performance Concretes, Superplasticizers, Compressive and flexural strengthAbstract

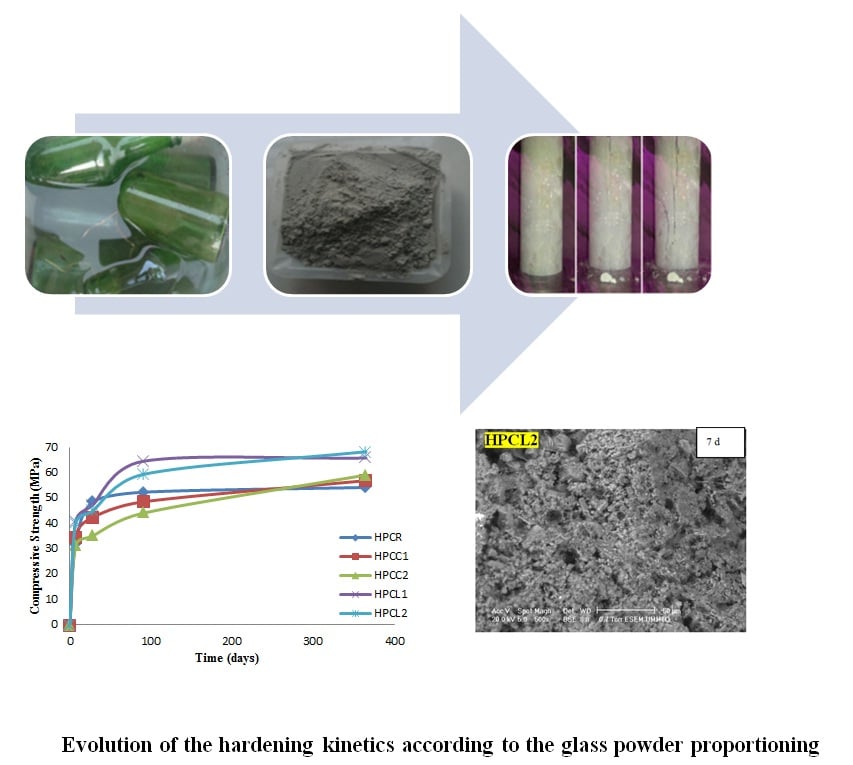

Recycling waste glass and protection of the environment with decreasing of the cement use in building are the main context of this research work. The influence of waste Glass Powder very rich in silica SiO2 as partial replacement of Algerian cement without additions based High Performance Concretes with superplasticizers is evaluated, varying the percentage of Glass Powder by 0%, 10% and 20% (by weight of cement). Compression and the three-point bending tests carried out on High Performance Concretes by fixing the water binder ratio and after water cement ratio at 0.35, the results show that the addition of Glass Powder improves the behaviour of the concrete material compared to the handling and the ease of implementation in an appreciable way. The study shows also that compressive and flexural strengths are significantly influenced by the substitution rate of Glass Powder, a drop is noticed at a young age for concrete with Glass Powder (7 and 28days) and strength gains at 90 and 365 days compared to the control concrete with 0%, this admitted that poozolanic and alkali silica reactions occurred from 28 days.

References

Yang KH, Jung YB, Cho MS, Tae SH. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. Journal of Cleaner Production. 2015;103:774-783.

Ogata K, Yang Y. Modern control engineering. India: Prentice hall; 2002.

Khudhair MH, Elyoubi MS, Elharfi A. Experimental study and modeling the rupture model of a new hydraulic binder based on the combination of inorganic additions by the response surface methodology. J Mater Environ Sci. 2017;8(6):1978-1989.

Meziani M, Leklou N, Amiri O, Chelouah N. Physical and mechanical studies on binary blended Portland cements containing mordenite-rich tuff and limestone filler. Matériaux & Techniques. 2019;107(3):303.

Kamali M, Ghahremaninezhad A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Construction and building materials. 2015;98:407-416.

Matos AM, Sousa-Coutinho J. Durability of mortar using waste glass powder as cement replacement. Construction and building materials. 2012;36:205-215.

Hendi A, Behravan A, Mostofinejad D, Moshtaghi SM, Rezayi K. Implementing ANN to minimize sewage systems concrete corrosion with glass beads substitution. Construction and Building Materials. 2017;138:441-454.

Khmiri A, Samet B, Chaabouni M. Assessment of the waste glass powder pozzolanic activity by different methods. International Journal of Research and Reviews in Applied Sciences. 2012;10(2):322-328.

Ali MH, Dinkha YZ, Haido JH. Mechanical properties and spalling at elevated temperature of high performance concrete made with reactive and waste inert powders. Engineering Science and Technology, an International Journal. 2017;20(2):536-541.

Arroudj K, Zenati A, Oudjit MN, Bali A, Tagnit-Hamou A. Reactivity of fine quartz in presence of silica fume and slag. Engineering. 2011;3(6):569-576

Vaitkevičius V, Šerelis E, Hilbig H. The effect of glass powder on the microstructure of ultra high performance concrete. Construction and Building Materials. 2014;68:102-109.

Bouzoubaâ N, Lachemi M. Self-compacting concrete incorporating high volumes of class F fly ash: Preliminary results. Cement and concrete research. 2001;31(3):413-420.

Schwarz N, Cam H, Neithalath N. Influence of a fine glass powder on the durability characteristics of concrete and its comparison to fly ash. Cement and Concrete Composites. 2008;30(6):486-496.

Prusty JK, Patro SK, Basarkar SS. Concrete using agro-waste as fine aggregate for sustainable built environment–A review. International Journal of Sustainable Built Environment. 2016;5(2):312-333.

Adanikin A, Funsho F, Olutaiwo A. Strength analysis of concrete pavement deformation due to Alkali Silica Reaction (ASR). Alg. J. Eng. Tech. 2020; 3: 20-27.

Idir R, Cyr M, Tagnit-Hamou A. Potential pozzolanicity of glass cullet fines and aggregates. InAnnales du Bâtiment et des Travaux Publics 2011 Feb 1 (No. 1, p. 28). Editions ESKA.

Shi C, Wu Y, Riefler C, Wang H. Characteristics and pozzolanic reactivity of glass powders. Cement and Concrete Research. 2005;35(5):987-993.

Du H, Tan KH. Waste glass powder as cement replacement in concrete. Journal of Advanced Concrete Technology. 2014;12(11):468-477.

Idir R, Cyr M, Tagnit-Hamou A. Can We Massively Reuse Glass In Concrete? Properties Of Glass Concrete. Verre. 2010;16:70-77.

Walczak P, Małolepszy J, Reben M, Rzepa K. Mechanical properties of concrete mortar based on mixture of CRT glass cullet and fluidized fly ash. Procedia Engineering. 2015;108:453-458.

Islam GS, Rahman M, Kazi N. Waste glass powder as partial replacement of cement for sustainable concrete practice. International Journal of Sustainable Built Environment. 2017;6(1):37-44.

Tuan BL, Hwang CL, Lin KL, Chen YY, Young MP. Development of lightweight aggregate from sewage sludge and waste glass powder for concrete. Construction and building materials. 2013;47:334-339.

Shevchenko V, Swierad W. A mechanism of portland cement hardening in the presence of finely grained glass powder. Chemistry & chemical technology. 2007. 1.

Saribiyik M, Piskin A, Saribiyik A. The effects of waste glass powder usage on polymer concrete properties. Construction and building materials. 2013;47:840-844.

Behim M, Boucetta TA. Valorisation du verre à bouteille comme addition fine dans les bétons autoplaçants. Déchets Sciences et Techniques. 2013;65:20-28.

Liu M. Incorporating ground glass in self-compacting concrete. Construction and Building Materials. 2011;25(2):919-25.

Sharifi Y, Houshiar M, Aghebati B. Recycled glass replacement as fine aggregate in self-compacting concrete. Frontiers of Structural and Civil Engineering. 2013;7:419-428.

Kou SC, Xing F. The effect of recycled glass powder and reject fly ash on the mechanical properties of fibre-reinforced ultrahigh performance concrete. Advances in Materials Science and Engineering. 2012;2012.

Yu R, Van Onna DV, Spiesz P, Yu QL, Brouwers HJ. Development of ultra-lightweight fibre reinforced concrete applying expanded waste glass. Journal of Cleaner Production. 2016;112:690-701.

Gahoi K, Kansal R. Effect of Waste Glass Powder on Properties of Concrete: A Literature Review. Int. J. Sci. Res. 2015:6-391.

Shekhawat BS, Aggarwal DV. Utilisation of waste glass powder in concrete–A Literature Review. International Journal of Innovative Research in Science, Engineering and Technology. 2014;3(7)822-826.

Ali EE, Al-Tersawy SH. Recycled glass as a partial replacement for fine aggregate in self-compacting concrete. Construction and Building Materials. 2012;35:785-791.

Limbachiya M, Meddah MS, Fotiadou S. Performance of granulated foam glass concrete. Construction and building materials. 2012;28(1):759-768.

Soliman NA, Tagnit-Hamou A. Development of ultra-high-performance concrete using glass powder–Towards ecofriendly concrete. Construction and building materials. 2016;125:600-612.

Tan KH, Du H. Use of waste glass as sand in mortar: Part I–Fresh, mechanical and durability properties. Cement and Concrete Composites. 2013;35(1):109-117.

Du H, Tan KH. Use of waste glass as sand in mortar: Part II–Alkali–silica reaction and mitigation methods. Cement and Concrete Composites. 2013;35(1):118-26.

Topcu IB, Canbaz M. Properties of concrete containing waste glass. Cement and concrete research. 2004;34(2):267-274.

Meyer C, Egosi N, Andela C. Concrete with waste glass as aggregate. InRecycling and reuse of glass cullet 2001 (pp. 179-188). Thomas Telford Publishing.

Degirmenci N, Yilmaz A, Cakir OA. Utilization of waste glass as sand replacement in cement mortar. Indian J Eng Mater Sci.2011;18:303-308.

Standard NF EN 197-1. Cement - Part 1: Composition, specifications and conformity criteria for common cements .2000

Standard NF EN 934-2. Admixtures for concrete, mortar and grout — Part 2: Concrete admixtures Definitions, requirements, conformity, marking and labeling .2002

Standard NF P 18-400. Béton, Moules pour éprouvettes cylindriques et prismatiques .1981

Standard NF P 18-451., Bétons Essai d’affaissement .1981

Standard NF EN 12390-3. Testing hardened concrete — Part 3: Compressive strength of test specimens .2003

NF EN 12390-5. Testing hardened concrete — Part 5: Flexural strength of test specimens. 2001

Redden R, Neithalath N. Microstructure, strength, and moisture stability of alkali activated glass powder-based binders. Cement and Concrete Composites. 2014;45:46-56.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Bahia Aissat Arab, Rachid Mehaddene

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.