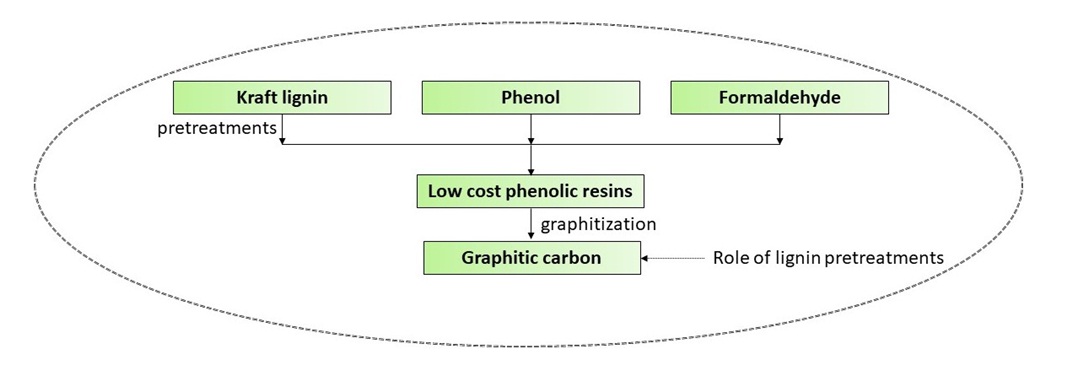

Graphitization of lignin-modified phenolic resins: role of lignin pretreatments

DOI:

https://doi.org/10.57056/ajet.v6i1.73Keywords:

Kraft lignin, Lignin-modified phenolic resin, Graphitic carbon, GraphitizationAbstract

Aiming at the generation of graphitic carbon from low-cost phenolic resins, this study investigated the role of lignin pretreatments on the amount of crystalline carbon generated from lignin-phenol-formaldehyde resins containing boron oxide, boric acid and ferrocene as graphitizing additives. Kraft lignin used to synthesize the resins was initially subjected to thermal and thermomechanical treatments to improve processability and promote greater mobility for ease of graphitization during carbonization. The results showed that the characteristics of lignin used to prepare the thermosetting resins affect the quantity of graphitic carbon that was generated during pyrolysis. The lignin-modified resin prepared using Kraft lignin, which has the lowest molecular weight and polydispersivity values produced the highest amount of graphitic carbon. This formulation containing 10 wt.% boric acid presents a graphitization level value of 73%. In addition, limited amounts of crystalline carbon were generated when boron oxide and ferrocene were used as graphitizing additives.

References

Alonso MV, Oliet M, Rodrı́guez F, Garcı́a J, Gilarranz MA, Rodrı́guez JJ, Modification of ammonium lignosulfonate by phenolation for use in phenolic resins. Bioresour. Technol. 2005, 96(9):1013-8,.

Lihong Hu HP, Yonghong Z, Meng Z. Method to improve lignin's reactivity as a phenol substitute and a replacement for other phenolic compounds: A brief review. Bioresour. 2011, 6(3):3515-3525.

Gardziella A, Pilato LA, Knop A. Phenolic Resins: Chemistry, Applications, Standardization, Safety and Ecology. 2 ed. New York: Springer-Verlag Berlin Heidelberg; 2000.

Gellerstedt G, Henriksson G. Chapter 9 - Lignins: Major Sources, Structure and Properties A2 - Belgacem, Mohamed Naceur. In: Gandini A, editor. Monomers, Polymers and Composites from Renewable Resources. Amsterdam: Elsevier; 201-224, 2008.

Talabi SI. Luz AP, Pandolfelli VC, Lima VH, Botaro VR, Lucas AA. Graphitization of Lignin-Phenol-Formaldehyde Resins. Mater. Res. 2020, 23(2):20190686(1-9).

Chen S, Xin Y, Zhao C. Multispectroscopic analysis in the synthesis of lignin-based biophenolic resins. ACS Sustainable Chem. Eng. 2021, 9(46):15653-15660.

Talabi SI, Luz AP, Lucas AA, Pagliosa C, Pandolfelli VC. Catalytic graphitization of novolac resin for refractory applications. Ceram. Int. 2018, 44(4):3816-3824.

Ren Y, Xie J, He X, Shi R, Liu C. Preparation of Lignin-Based High-Ortho Thermoplastic Phenolic Resins and Fibers. Mol. 2021, 26(1):3993.

Talabi SI, Luz AP, Pandolfelli VC, Bernardes JS, Lucas AA. Synthesis and graphitization of resole resins by ferrocene. Prog. Nat. Sci.: Mater. Int. 2019, 29(1):71-80.

Bitencourt CS, Luz AP, Pagliosa C, Pandolfelli VC, Role of catalytic agents and processing parameters in the graphitization process of a carbon-based refractory binder. Ceram. Int. 201, 41(10):13320-13330.

Talabi SI, Luz AP, Pandolfelli VC, Lucas AA. Structural evolution during the catalytic graphitization of a thermosetting refractory binder and oxidation resistance of the derived carbons. Mater. Chem. Phys. 2018, 212:113-121.

Al-Falahi HA, Catalytic Graphitization of Modified Phenolic Resin and its Nanoparticles Fillers Behavior towards High Temperature. Adv. Mater. Res. 2014, 925:282-289,.

Vázquez-Santos MB, Geissler E, László K, Rouzaud J-N, Martínez-Alonso A, Tascón JMD. Comparative XRD, Raman, and TEM Study on Graphitization of PBO-Derived Carbon Fibers. J. Phys. Chem. 2012, 116(1):257-268.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Segun Talabi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.