Investigation of the mechanical properties of annealing heat treated low carbon steel

DOI:

https://doi.org/10.57056/ajet.v6i1.70Keywords:

Heat Treatment, Microstructure, Tensile Test, Hardness Test, Mechanical PropertiesAbstract

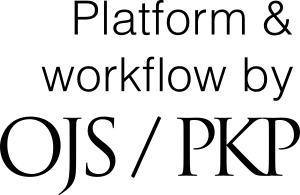

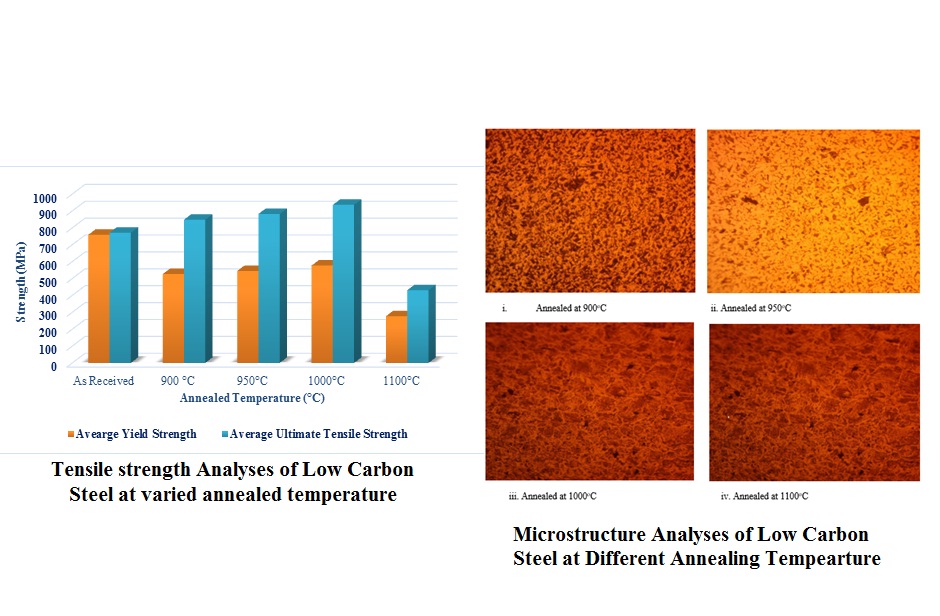

The mechanical properties of steel materials usually vary under different conditions, thus choosing the suitable heat treatment is needed to obtain acceptable properties. In this research work, investigation of the mechanical properties of heat treated low carbon steel was determined using tensile tests, and hardness measurements. Also, the microstructure of the samples was characterized by means of optical microscopy. The samples of low carbon steels were sourced at local market in Nigeria. The collected samples were machined using lathe machine to a diameter of 10mm and gauge length of 30 mm. The chemical composition of the steel was determined using X-ray fluorescence spectroscopy. The mechanical properties of the heat treated and untreated samples were investigated at the temperatures of 900 ⁰C, 950 ⁰C, and 1000 ⁰C. The results obtained show that the ultimate tensile strength and percentage elongation of samples increases after heat treatment. Also, yield strength and hardness tend to decrease for all annealed heat treated samples at different temperature as compared to as received samples. The results of the microstructural analyses of the as received samples showed fine dispersion of coalesced pearlite and ferrite grain. For the annealed samples, the steel microstructures compose of martensite distributed in the ferrite matrix. However, with increase in annealing temperature to 1000 ⁰C and 1100 ⁰C cementite and ferrite grain with partial grain boundary were observed.

References

Sanij MHK, Banadkouki SSG, Mashreghi AR, Moshrefifar M. The effect of single and double quenching and tempering heat treatments on the microstructure and mechanical properties of AISI 4140 steel. Mater. Des. 2012; 42:339–46

Bardelcik A, Worswick, MJ, and Wells, M. The influence of martensite, bainite and ferrite on the as-quenched constitutive response of simultaneously quenched and deformed boron steel, experiments and model. Mater. Des. 2014; 55: 509–25

Offar PO, Daniel CC, Obikwelu DON. Effects of various quenching media on the mechanical propertied of intercritically annealed 0.15 wt.% C-0.43wt% Mn steel. Nigerain J. of Techno. 2010; 29 (2): 76-81

Adeyemi TMB, Adedayo SM. Vegetable Oils as Quenchants for Hardening Medium Carbon Steel. J. of App. Sci. and Tech. 2009; 14: 74-78

Fadare DA, Fadara TG, Akanb OY. Effect of Heat Treatment on Mechanical Properties and Microstructure of NST37-2 Steel. J. of Min. and Mat. Char. and Eng. 2011; 10: 299-308

Abbasi E, Luo Q, Owens D. A comparison of microstructure and mechanical properties of Low-Alloy-Medium-Carbon steels after quench-hardening. Mater. Sci. and Eng. 2015; 725: 65–75

Phetlam P, Uthaisangsuk V. Microstructure based flow stress modeling for quenched and tempered low alloy steel. Mater. Des. 2015; 82: 189–99

Torkamani H, Raygan S, Rassizadehghani J. Comparing microstructure and mechanical properties of AISI D2 steel after bright hardening and oil quenching. Mater. Des, 2014; 54(10): 49–55

Orhorhoro EK, Erameh AA, Adingwupu AC. Evaluation of the effect of tempering on the corrosion susceptibility of low carbon steel in sea water. Nigerian Resech. J. of Eng. and Environ. Sci. 2018; 3(1): 409-415

Torkamani H, Raygan S, Rassizadehghani J. Comparing microstructure and mechanical properties of AISI D2 steel after bright hardening and oil quenching. Mater. Des. 2014; 54: 1049–55

Tao X, Li C, Han L, Gu J. Microstructure evolution and mechanical properties of X12CrMoWVNbN10-1-1 steel during quenching and tempering process. J. of Mat. Resec and Tech. 2015; 5: 45–57

Agboola JA, Kamardeem OA, Mudiare E, Adeyemi MB, Afolabi AS. Performance assessment of selected Nigerian vegetable oils as quenching media in hardening process for medium carbon steel. J. of Min. and Mat. Char. and Eng. 2015; 3: 85-93

Wang C, Qiu H, Kimura Y, Inoue T. Morphology, crystallography, and crack paths of tempered lath martensite in a medium carbon low alloy steel. Mat. Sci. and Eng. 2013; 669: 48–57

Al-Qawabah SMA, Nabeel A, Al-Qawabeha UF. Effect of Annealing Temperature on the Microstructure, Microhardness, Mechanical Behavior and Impact Toughness of Low Carbon Steel, Grade 45. Int. J. of Eng. Res. and Appl, 2012; 2 (3): 1550-1553.

Onyekpe B. The Essentials of Metallurgy and Materials in Engineering, AMBIK PRESS, Nigeria, ISBN 978-8016-53-7, 2002

Ajayi JA, Joseph OO, Oloruntoba DT and Joseph OO. Experimental Failure Investigation of and Aircraft Nose Landing Gear. Int. J. of Met. and Mat. Eng., 2013; 3(1): 85-92.

Joseph OO, Abidakun OA, Aniyikaye AO, Folorunsho OO. Investigations on the Material Efficacy of Failed Helical Gears in a Gear Train. Ind. Eng. Let. 2013; 3(6): 46-54.

Raji NA, Oluwole OO. Effect of Soaking Time on the Mechanical Properties of Annealed Cold-Drawn Low Carbon Steel, Mat. Sci. and Appl. 2012; 3: 513-518

Iron C. Microstructure and Mechanical Properties of Martensitic Stainless Steel 6CrlSMoV, 2012, 19(3): 56–61

Hamza E, Saoussan E, Said E, Elhachmi E. Heat treatment effect on mechanical properties of AISI 304 of austenitic stainless steel. 2nd International Conference on Sustainable Materials Processing and Manufacturing, Science Direct, Procedia Manufacturing, 2019; 32: 883-888

Oluwagbenga TJ, Enoch NO, Albert UU, Norman G, Richard A. Mechanical Properties of Heat-treated Medium Carbon Steel in Renewable and Biodegradable Oil. 2nd International Conference on Sustainable Materials Processing and Manufacturing, Science Direct, Procedia Manufacturing, 2019; 35: 229-235

Odusote JK, Ajiboye TK. Evaluation of Mechanical Properties of Medium Carbon Steel Quenched in Water and oil. J. of Minerals and Mat. Characterization and Eng. 2012: 218-224

Tukur SA, Dambatta MS, Ahmed A, Mu’az NM. Effect of Heat Treatment Temperature on Mechanical Properties of the AISI 304 Stainless Steel. Inter. J. of Innovative Res. in Sci., Eng. and Tech. 2014; 3(2):9516-9520

Callister DW. Materials Science and Engineering: An Introduction, 7th Edition, John Wiley and Sons Incorporation, UK

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ejiroghene Kelly Orhorhoro, Andrew Amagbon Erameh, Silas Oseme Okuma

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.