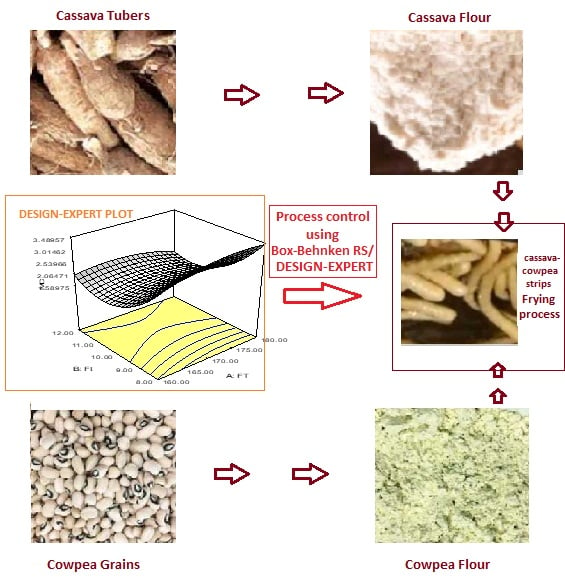

Modeling and optimization of processing parameters of strips produced from blends of cassava and cowpea flour

DOI:

https://doi.org/10.57056/ajet.v7i1.6Keywords:

Box-Behnken Design, Frying Temperature, Frying Time, Optimization, Quality AttributesAbstract

Most Nigerian traditional foods have a low nutritional value, inconsistent sensory attributes, and short shelf life. Thus, upgrading becomes necessary for the technologies used in the processing, distributing, and storing of indigenous snack foods to improve the products' nutritional, sensory, and storage properties. A Box-Behnken (three-factor) response surface methodology was used to optimize the process. The effect of frying temperature (160 - 180°C), frying time (8 - 12 min) and percent cowpea flour (10 - 30%) on some attributes (moisture, fat, protein contents, texture, and color change) of cassava-cowpea strips fried snack. Data were analyzed by ANOVA and regression analysis. The moisture content ranged between 1.00% and 4.26%, fat content (8.41–11.94%), protein content (30.83–36.42%), texture (5.06–13.14 N) and color change (26.967–40.479). Frying temperature, frying time and % cowpea flour had a significant (P < 0.05) effect on moisture, fat, protein contents, texture and color change of cassava-cowpea strips. The processing conditions affected moisture, fat, protein, texture, and color change. Coefficients of determination, R2 were 0.87, 0.86, 0.79, 0.88 and 0.71, respectively. The best conditions for processing cassava-cowpea strips were 12 min frying time, 166.65 °C frying temperature, and 24.36% cowpea flour content. The desirability of optimization was 0.65. Therefore, composite flour from cassava and cowpea can be adopted or used to produce strips to prevent protein-energy malnutrition in the community.

References

Maziya-Dixon B, Alamu EO, Popoola IO, Yomeni M. Nutritional and sensory properties: Snack food made from high-quality cassava flour and legume blend. Food Science and Nutrition. 2017;5:805–811.

Oluwamukomi MO, Oluwalana IB, Akinbowale OF. Physicochemical and sensory properties of wheat-cassava composite biscuit enriched with soy flour. African Journal of Food Science. 2011;5(2):50–56.

Nweke FI., Spencer DSC, Lynam JK. The cassava transformation: Africa's best-kept secret. Michigan University Press, USA. 2002.

Aniedu C, Omodamiro RM. “Cassava (Manihot esculenta)”. Global Journal of Science Frontier Research Agriculture and Veterinary Sciences. 2012;12(10):2249–4626.

Dada TA, Barber LI, Ngoma L, Mwanza M. Formulation, sensory evaluation, proximate composition, and storage stability of cassava strips produced from the composite flour of cassava and cowpea. Food Science Nutrition. 2018;6:395-399.

Olalekan AJ, Bosede BF. Comparative study on chemical composition and functional properties of three Nigerian legume (Jack beans, pigeon pea and cowpea). Journal of Emerging Trends in Engineering and Applied Sciences. 2010;1:89–95.

Liyanage R, Perera OS, Wethasinghe P, Jayawardana BC, Vidanaarachchi JK, Sivaganesan R. Nutritional properties and antioxidant content of commonly consumed cowpea cultivars in Sri Lanka. Journal of Food Legumes (Formerly Indian Journal of Pulses Research), 2014; 27(3):215-217.

Myers RH, Montgomery DC, Anderson-Cook CM. Response Surface Methodology: Process and Product Optimization Using Designed Experiments. (4th edition) New York, USA, John Wiley & Sons. 2009.

Akinoso R, Adeyanju JA. Optimization of edible oil extraction from ofada rice bran using response surface methodology. Food and Bioprocess Technology: An International Journal. 2012;5:1372–1378.

Adeyanju JA, Olajide JO, Adedeji AA. Optimisation of deep-fat frying of plantain chips (ipekere) using response surface methodology. Journal of Food Processing and Technology, 2016;7:584–590.

Idowu AO, Aworh OC. Modeling and optimization of processing variables of snack (kokoro) produced from blends of maize and African yam bean seed flour. International Food Research Journal, 2017;24(2): 607-613.

AOAC. Official methods of Analysis, Association of Officiating Analytical Chemists, 18th Ed. Gaithersburg, Maryland, Method 925.10, 960.25 and 2003.03. 2005.

DaSilva, PF, Moreira RG. Vacuum frying of high-quality fruit and vegetable-based snacks. LWT-Food Science and Technology. 2008;41:1758-1767.

Krokida MK, Oreopoulou V, Maroulis ZB, Marinos-Kouris D. Color changes during deep-fat frying of French fries . Journal of Food Engineering. 2001;48:219-225.

Eshun G. Nutrient composition and functional properties of bean flours of three soya bean varieties from Ghana. African Journal of Food Science and Technology, 2012;3(8), 176 181.

Moss R, Gore PJ, Murray IC. The influence of ingredients and processing variables on the quality and microstructure of Hokkien, cantonese and instant noodles. Food Structure, 1987;l6(1): 8-9.

Aiyesanmi AF, Oguntokun MO. Nutrient composition of Dioclea reflexa seed: An underutilized edible legume. Rivista Italiana delle Sostanze Grasse, 1996;73: 521–523.

Ihekoronye AI, Ngoddy PO. Integrated Food Science and Technology for the tropics. Macmillan Publishers, pp. 368 -369, London, 1985.

Brown KH. The importance of dietary quality versus quantity for weanlings in the developed countries. A Framework for Discussion. Food and Nutrition Bulletin, 1991;13(2):86-93.

Olalekan AJ, Bosede BF. Comparative study on chemical composition and functional properties of three Nigerian legume (Jack beans, pigeon pea and cowpea). Journal of Emerging Trends in Engineering and Applied Sciences, 2010;1:89–95.

Temple VJ, Bassa JD. Proximate chemical composition of acha (Digitaria exilis) grain. Journal of the Science of Food and Agriculture. 1991;56(4):561–563.

Chambers E, Bowers JR. Consumer perception of sensory qualities in muscle foods. Food Technology, 1993;47(11):116–20.

Nourian F, Ramaswamy HS. Kinetics of quality changes during cooking and frying of potatoes: Part 1. Texture. Journal of Food Process Engineering. 2003;26: 377-394.

Idowu AO, Aworh OC. Optimization of some processing conditions for kokoro production using response surface methodology. Agricultural Engineering International: CIGR Journal, 2014;16(2):187-195.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 James Abiodun Adeyanju, Adekanmi Olusegun Abioye, Grace Oluwatoyin Ogunlakin, Olusegun James Oyelade, Deborah Adeola Adesina, Abiola Adewale Oloyede

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.