Evaluation of rice milling quality and energy requirement via a developed vibratory rice grader

DOI:

https://doi.org/10.57056/ajet.v7i1.3Keywords:

Energy intensity, Energy requirement, Milling quality, Grading, Processing ConditionsAbstract

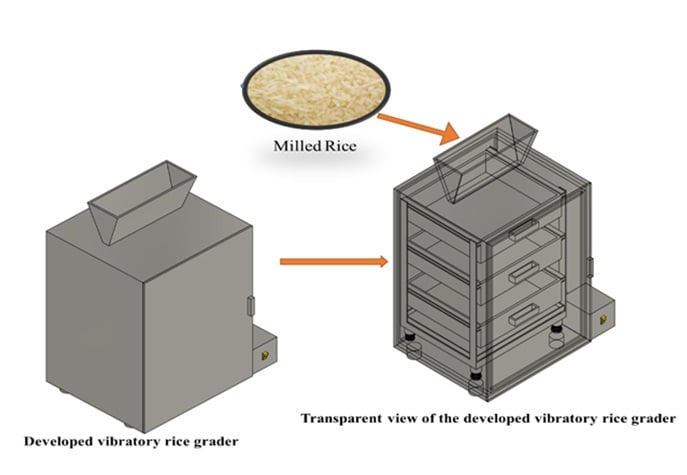

In the modern way of processing rice, rice is usually parboiled before milling operation and grading is one of the milling operations required to classify rice into different grades of importance viz. the head and broken rice. In this study, a vibratory rice grader was developed. The effect of processing conditions on the milling quality (milling recovery, head milled rice and broken rice), grading time, energy requirement and energy intensity were evaluated. The soaking time (4 – 6 h), steaming time (30 – 40 mins) and rice variety (FARO 15, FARO 60 and FARO 62) were interacted using Taguchi experimental design (L933). Standard equations were used to evaluate the effect of processing conditions on the milling quality, energy requirement and energy intensity of the rice grader. Milling recovery ranged from 53% to 70%, head milled rice (41% - 67%), broken milled rice (3% - 12%), grading time (4.4 – 5.8 mins), energy requirement (2.632 MJ to 2.649 MJ) and energy intensity (1.20 – 1.58 MJ/kg). An increase in soaking time and steaming time increased the grading time, milling recovery, head milled rice, energy requirement and energy intensity but reduced the broken milled rice. The estimated cost of the developed vibratory rice grader was $152. This study provides valuable information on a simple way of designing and developing a rice grader that could be adopted for grading rice into whole rice or head rice and broken rice.

References

Dogara AM, Jumare AI. Origin, distribution and heading date in cultivated rice. International Journal of Plant Biology and Research. 2014, 2;1: 2–6.

Adebowale ARA, Sanni LO, Owo HO, Karim OR. Effect of variety and moisture content on some engineering properties of paddy rice. Journal of Food Science and Technology. 2011, 48;5: 551-559.

Danbaba N, Anounye JC, Gana AS, Abo ME, Ukwungwu MN, Maji AT. Physical and pasting properties of ‘ofada’rice (Oryza sativa L.) varieties. Nigerian Food Journal, 2012, 30;1: 18-25.

Sanusi MS, Akinoso R. Multiobjective optimization of parboiled rice quality attributes and total energy consumption. Nigerian Journal of Technological Research. 2020, 15;3: 24-33.

Meresa A, Demissew A, Yilma S, Tegegne G, Temesgen K. Effect of parboiling conditions on physical and cooking quality of selected rice varieties. International Journal of Food Science, 2020.

Chavan P, Sharma SR, Mittal TC, Mahajan G, Gupta S K. Effect of parboiling technique on physico-chemical and nutritional characteristics of basmati rice. Agricultural Research Journal, 2018: 55;3: 490-499.

Sanusi MS, Akinoso R. Modelling and optimising the impact of process variables on brown rice quality and overall energy consumption. International Journal of Postharvest Technology and Innovation. 2021: 8;1, 70-88.

Karunarathna KDN, Buddhika, AN, Kahatapitiya, KRMG, Gunasekera MY. Hydration characteristics of paddy in the parboiling process. 2010. University of Moratuwa Sri Lanka, http://dl.lib.mrt.ac.lk/handle/123/11696.

Bhattacharya KR. Parboiling of rice: rice chemistry and technology. American Association of Cereal Chemists Inc. in Champagne ET, ed. 2004: 329–404.

Elbert G, Tolaba MP, Suárez C. Effects of drying conditions on head rice yield and browning index of parboiled rice. Journal of Food Engineering. 2001: 47;1, 37-41.

Ayamdoo AJ, Demuyakor B, Saalia FK, Francis A. Effect of varying parboiling conditions on the cooking and eating/sensory characteristics of Jasmine 85 and Nerica 14 rice varieties Savanna Agricultural Research Institute; 2014 http://hdl.handle.net/123456789/1090.

Sanusi MS, Akinoso R, Danbaba N. Evaluation of physical, milling and cooking properties of four new rice (Oryza sativa L.) varieties in Nigeria. International Journal of Food Studies. 2017, 6;2.

Bao, J. Rice milling quality. In Rice. AACC International Press. 2019. 339-369.

Chathurika SS, Upul S. Classification of rice grains using neural networks. Proceedings of Technical Sessions, 2013, 29: 9–14.

Piramli MM, Rahman AFNA, Abdullah SF. Rice grain grading classification based on perimeter using moore-neighbor tracing method. Journal of Telecommunication, Electronic and Computer Engineering (JTEC). 2016. 8;2: 23-27.

Okunola AA, Isaac-Bamgboye A, Olayanju TMA, Osueke CO, Alahassan EA 2018. Development of a rice cleaner cum grader for cottage industry processors in Nigeria. International Journal of Mechanical Engineering and Technology. 2018, 9;11: 2339-2351.

Yayock ES, Ishaya J. Development and performance evaluation of a grain grading machine for small and medium scale farmers. IOSR Journal of Agriculture and Veterinary Science (IOSR-JAVS). 2020, 13;10: 33–40.

Roy P, Ijiri T, Okadome, H, Nei D, Orikasa T, Nakamura N. Shiina T. Effect of processing conditions on overall energy consumption and quality of rice (Oryza sativa L.). Journal of Food Engineering. 2008; 89;3, 343-348.

Bird J. Bird's engineering mathematics. Routledge. 2021, 9th Edition.

Young HD, Freedman RA. University physics with modern physics Sears, Francis Weston, United States of America: Pearson Education, Inc., publishing as Addison-Wesley. 2012.

Katayama N, Odaya Y, Amano T, Yoshida H. Spatial and temporal associations between fallow fields and Greater Painted Snipe density in Japanese rice paddy landscapes. Agriculture, Ecosystems and Environment. 2020; 295: 106892.

Bello MO, Loubes MA, Aguerre RJ, Tolaba MP. Hydrothermal treatment of rough rice: effect of processing conditions on product attributes. Journal of Food Science and Technology. 2015; 52;8: 5156-5163.

Nasirahmadi A, Emadi B, Abbaspour-Fard MH, Aghagolzade H. Influence of moisture content, variety and parboiling on milling quality of rice grains. Rice Science. 2014, 21;2: 116-122.

Danbaba N, Nkama I, Badau MH, Ukwungwu MN, Maji AT, Abo ME, Oko AO. Optimization of rice parboiling process for optimum head rice yield: a response surface methodology (RSM) approach. Focus, 2014; 18: 19.

Parnsakhorn S, Noomhorm, A. Changes in physicochemical properties of parboiled brown rice during heat treatment. Agricultural Engineering International: CIGR Journal. 2008.

Chavan P, Sharma SR, Mittal TC, Mahajan G, Gupta SK. Optimization of parboiling parameters to improve the quality characteristics of Pusa Basmati 1509. Journal of Food Process Engineering. 2017, 40;3: e12454.

Kapur T, Kandpal TC, Garg HP. 1997. Rice processing in India: a generalized framework for energy demand estimation. International Journal of Energy Research. 1997, 21;4: 309-325.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Mayowa Saheed SANUSI, Musiliu Olushola Sunmonu, Jelili Babatunde Hussein, Sodiq Ayinde Olaleye, Ifeoluwa Benjamin Adedeji, Ganiyu Oluwaseyi Hamzat, Israel Tomiwa Popoola

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.