Effect of Guinea Corn Husk Ash (GCHA) on the compressive strength and water absorption of mortar

DOI:

https://doi.org/10.57056/ajet.v9i2.185Keywords:

Mortar, Guinea Corn Husk Ash, Cement, Compressive Strength, Water AbsorptionAbstract

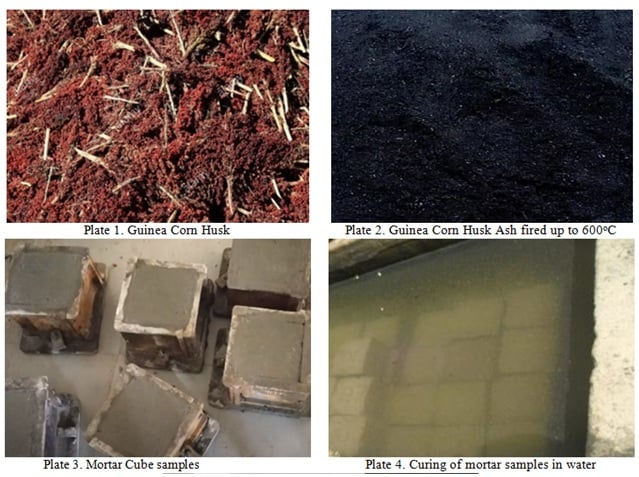

In this research work, the weight loss, compressive strength, and water absorption of samples of cured mortar are measured to assess the effects of adding a 2% increment of GCHA content into the mortar mixture as a partial replacement of cement to determine how this addition affects the strength and other physical properties of the mortar samples produced. Compressive strength, slump, and water absorption tests were conducted according to BS EN 12390-3 (2009), BS EN 12350-2 (2009), and BS 1881-122 (2011) respectively. The results show that adding GCHA into mortar mix improves the mortar's strength up to 4% replacement level before it starts to decline. Moreover, adding more GCHA to mortar increases the mortar slump and water absorbance while density decreases. In addition, the study also reveals that GCHA-containing mortar is easier to handle than the control sample. These findings collectively support the potential of incorporating agricultural waste material in construction practices to achieve environmentally sustainable and durable building materials.

References

Aburime PI, Ndububa EE, Kpue DO. The Impact of Guinea Corn Husk Ash as an Admixture for Crack Control in Concrete. Eur J Eng Technol Res. 2020;5(10):1152–9. https://doi.org/10.24018/ejeng.2020.5.10.2171

Ndububa E, Yakubu N, Al. Effect of Guinea Corn Husk Ash as Partial Replacement for Cement in Concrete S0 3 in trace quantities. 2015. https://doi.org/10.9790/1684-12214045

Odeyemi IO, Okunade TA, Babalola OA, Sani MA. Experimental investigation of guinea corn husk ash as partial replacement of cement in mortar. J Mater Res Technol. 2020;9(3):5581–8. https://doi.org/10.1016/j.jmrt.2020.04.053

Odeyemi SO, Anifowose M, Abdulwahab R, Oduoye W. Mechanical Properties of High-Performance Concrete with Guinea Corn Husk Ash as Additive. 2020;5:139–54. https://doi.org/10.36108/laujoces/0202/50(0131)

Odeyemi SO, Atoyebi O, Emmanuel A. Effect of Guinea Corn Husk Ash on the Mechanical Properties of Lateritic Concrete. IOP Conf Ser Earth Environ Sci. 2020;445:012034. https://doi.org/10.1088/1755-1315/445/1/012034

Alex A, Kemal Z, Gebrehiwet T, Getahun S. Effect of α: phase nano al2o3 and rice husk ash in cement mortar. Adv Civ Eng. 2022;2022:1–8. https://doi.org/10.1155/2022/4335736

Mehdizadeh B, Jahandari S, Vessalas K, Miraki H, Rasekh H, Samali B. Fresh, mechanical, and durability properties of self-compacting mortar incorporating alumina nanoparticles and rice husk ash. Materials. 2021;14(22):6778. https://doi.org/10.3390/ma14226778

Saand A, Ali T, Keerio M, Bangwar D. Experimental study on the use of rice husk ash as partial cement replacement in aerated concrete. Eng Technol Appl Sci Res. 2019;9(4):4534–7. https://doi.org/10.48084/etasr.2903

Thiedeitz M, Schmidt W, Härder M, Kränkel T. Performance of rice husk ash as supplementary cementitious material after production in the field and in the lab. Materials. 2020;13(19):4319. https://doi.org/10.3390/ma13194319

Odeyemi S, Abdulwahab R, Akinpelu M, Afolabi R, Atoyebi O. Strength properties of steel and bamboo reinforced concrete containing quarry dust, rice husk ash and guinea corn husk ash. Iranica J Energy Environ. 2022;13(4):354–62. https://doi.org/10.5829/ijee.2022.13.04.05

Raheem A, Adedokun S, Uthman Q, Adeyemi A, Oyeniyi O. Application of corn husk ash as partial replacement for cement in the production of interlocking paving stones. Lautech J Civ Environ Stud. 2018;1(March):14–20. https://doi.org/10.36108/laujoces/8102/10(0130)

Sakib N, Hasan R, Mutalib A, Jamil M, Raman S, Kaish A. Utilization of sugar mill waste ash as pozzolanic material in structural mortar. Minerals. 2023;13(3):324. https://doi.org/10.3390/min13030324

Zhang W, Liu H, Liu C. Impact of rice husk ash on the mechanical characteristics and freeze–thaw resistance of recycled aggregate concrete. Appl Sci. 2022;12(23):12238. https://doi.org/10.3390/app122312238

Hsino M, Jasiczak J. Decision-making model using the Analytical Hierarchy Process for the selection of the type of concrete and the method of its maintenance in dry, hot climate conditions. Arch Civ Eng. 2023;69(3):385–403. https://doi.org/10.24425/ace.2023.146087

Hsino M, Jankowiak T, Jasiczak J. Experimental and numerical analysis of the concrete maturation process with additive of phase change materials. Materials. 2022;15(13). https://doi.org/10.3390/ma15134687

Horák J, Kuboňová L, Dej M, et al. Effects of the type of biomass and ashing temperature on the properties of solid fuel ashes. Pol J Chem Technol. 2019;21(2):43–51. https://doi.org/10.2478/pjct-2019-0019

Sam J. Compressive strength of concrete using fly ash and rice husk ash: a review. Civ Eng J. 2020;6(7):1400–10. https://doi.org/10.28991/cej-2020-03091556

British Standard Institution. BS 12: Specification for Portland cement. London; 1996.

British Standard Institution. BS 812: Methods for Sampling and Testing of Mineral Aggregates, Sands and Fillers. Part 103. London; 1995.

British Standards Institution. BS EN 1008: Mixing Water for Concrete. Specification for Sampling, Testing, and Assessing the Suitability of Water. London; 2002.

ASTM International. Standard Test Method for Density of Hydraulic Cement (ASTM C188-17). 2017.

British Standard Institution. BS EN 197, Part 1. Composition, Specification, and Conformity Criteria for Common Cements. London; 2011.

British Standard Institution. BS 812-103.2. Method of determination of particle size distribution. London; 1989.

British Standard Institution. BS 812, Part 3. Methods for Determination of Mechanical Properties. London; 1989.

British Standard Institution. BS 882, Part 2. Grading limits for fine aggregates. London; 1992.

British Standard Institution. BS EN 12390, Part 3. Method for Determination of Compressive Strength of Concrete Cubes. London; 2009.

British Standard Institution. BS 1881-122. Method for determination of water absorption. London; 2011.

ASTM International. Standard test method for water absorption of plastics (ASTM D570-98). 1998. Retrieved from https://www.astm.org/Standards/D570.htm

British Standard Institution. BS EN 12350-2. The Standard for Testing Fresh Concrete - Slump-test. London; 2009.

Oyedepo OJ, Babalola OO, Oyedepo SO. Utilization of guinea corn husk ash as partial replacement for cement in mortar. J Mater Environ Sci. 2015;6(6):1726–33.

Odeyemi IO, Okunade TA, Babalola OA, Sani MA. Experimental investigation of guinea corn husk ash as partial replacement of cement in mortar. J Mater Res Technol. 2020;9(3):5581–8. https://doi.org/10.1016/j.jmrt.2020.04.053

Smith AB, et al. Sustainable utilization of guinea corn husk ash (GCHA) in mortar. J Sustain Constr Mater Technol. 2018;8(1):36–43.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Sikiru Abdulganiyu Siyanbola

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.