Optimization of a gas-fired gurasa (local bread) baking oven using response surface methodology (RSM)

DOI:

https://doi.org/10.57056/ajet.v7i1.13Keywords:

Gas-fired, Gurasa, Baking oven, OptimizationAbstract

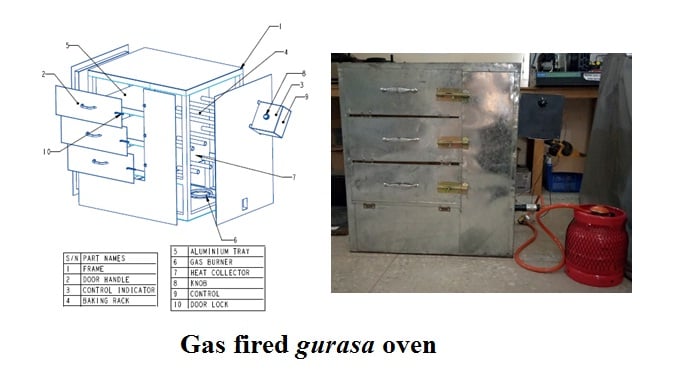

Gurasa (local bread) is an important diet in many households in Northern parts of Nigeria for time immemorial, especially in Kano State, Nigeria. This study is to develop a gurasa baking oven, carry out the performance evaluation of the oven and also to optimize the baking parameters of the oven using the response surface methodology (RSM). The oven is composed of three baking compartments; these include a heat source, a control panel and the main frame. The baking compartments consist of heating rods and the gurasa baking trays. The heat source is a gas burner that generates the required heat to bake the products. There is a control panel that is used to set the temperature at which the gas cylinder goes off (after the preheating of the oven) and the heat in the oven is maintained for some time with the aid of the insulator in between the walls. Using the response surface method, the oven was evaluated to know its baking efficiency, baking damage, and capacity. The oven has a baking efficiency of 87.5 %, baking damage of 11.5 % and a capacity of 23.4 kg/hr with 27 loaves per batch. The RSM showed values of the responses ranged from 16 – 95 g, 5.24 – 13.6 %, 845.8 – 3684.2 N/m2 and 0.7–8.06 cm3/g for weight loss, moisture content, tensile strength and specific volume respectively. Quadratic models to predict weight loss, moisture content, tensile strength and specific volume of gurasa in terms of baking temperature, baking period and mass of dough were developed. The optimum baking process was achieved at a baking temperature of 200oC, a baking period of 9 minutes and a dough mass of 130 g. These values show that the oven can be adopted for domestic and commercial baking.

References

Morakinyo AT, Omidiji B, Owolabi H. Development and optimization of operational parameters of a gas-fired baking oven. Leonardo J Sci [Internet]. 2017;(31):45–64. Available from: http://ljs.academicdirect.org/A31/045_064.pdf

Sepp S . Multiple-Household Fuel Use - A balanced choice between firewood, charcoal and LPG. [Internet]. Published by the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH. Printed by Metzgerdruck, Obrigheim / Germany Printed on FSC-certified paper.; 2014. 48 p. Available from: https://energypedia.info/images/3/32/2014-03_Multiple_Household_Cooking_Fuels_GIZ_HERA_eng.pdf

Bailis R Ezzati M, Kammen DM, Kituyi E. PD. Impacts of greenhouse gas and particulate emissions from wood fuel production and end-use in sub-Saharan Africa. 2007;2007(January):1–5.

IHME. Institute for Health Metrics and Evaluation (IHME), Global Burden of Disease Study (GBD) 2010. , Seattle, USA. [Internet]. 2012. Available from: https://ghdx.healthdata.org/record/ihme-data/gbd-2010-results-cause-1990-2010

Genitha I., G. B. T. Lakshmana DRJ. Design, Fabrication and Performance Evaluation of Domestic Gas Oven. IOSR J Eng [Internet]. 2014 May;4(5):35–8. Available from: http://www.iosrjen.org/Papers/vol4_issue5 (part-5)/G04553538.pdf

Alimasunya E, Yahaya O, Muhammed N. Development and Evaluation of Charcoal-Powered Bread Baking Oven. Appl Sci Reports [Internet]. 2016;16(3):23–30. Available from: http://anale-ing.uem.ro/2016/2.pdf

Chukwuneke JL, Nwuzor IC, Anisiji EO, Digitemie IE. Design and Fabrication of a Dual Powered Baking Oven. Adv Res. 2018;16(4):1–8.

Ilesanmi OE, Akinnuli BO. Design, Fabrication and Performance Evaluation of a Domestic Gas Oven. J Eng Res Reports [Internet]. 2019;5(1):1–10. Available from: https://www.journaljerr.com/index.php/JERR/article/download/16917/31453

Kamal MM, Ali MR, Shishir MRI, Saifullah M, Haque MR, Mondal SC. Optimization of process parameters for improved production of biomass protein from Aspergillus niger using banana peel as a substrate. Food Sci Biotechnol [Internet]. Springer Singapore; 2019;28(6):1693–702. Available from: https://doi.org/10.1007/s10068-019-00636-2

Islam Shishir MR, Taip FS, Aziz NA, Talib RA, Hossain Sarker MS. Optimization of spray drying parameters for pink guava powder using RSM. Food Sci Biotechnol [Internet]. 2016;25(2):461–8. Available from: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6049211/

Sumnu G, Ndife MK, Bayindirh L. Temperature and Weight Loss Profiles of Model Cakes Baked in the Microwave Oven. J Microw Power Electromagn Energy [Internet]. 1999 Jan 14;34(4):221–6. Available from: http://www.tandfonline.com/doi/full/10.1080/08327823.1999.11688409

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Sarafadeen Kolawole Shittu, Abdulkadir Ozemarisi Suleiman, Aliyu Idris Muhammad

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.